Exploring Advanced Diamond Grinding Techniques

- Philix

- Oct 22, 2025

- 4 min read

When it comes to precision and durability in industrial manufacturing, diamond grinding methods stand out as a game-changer. I’ve spent years working with various grinding techniques, and I can tell you that mastering these advanced methods can significantly improve your production quality and efficiency. Whether you’re smoothing out hard materials or preparing surfaces for further processing, diamond grinding offers unmatched performance.

Let’s dive into the world of diamond grinding and explore how you can leverage these techniques to elevate your craft.

Understanding Diamond Grinding Methods

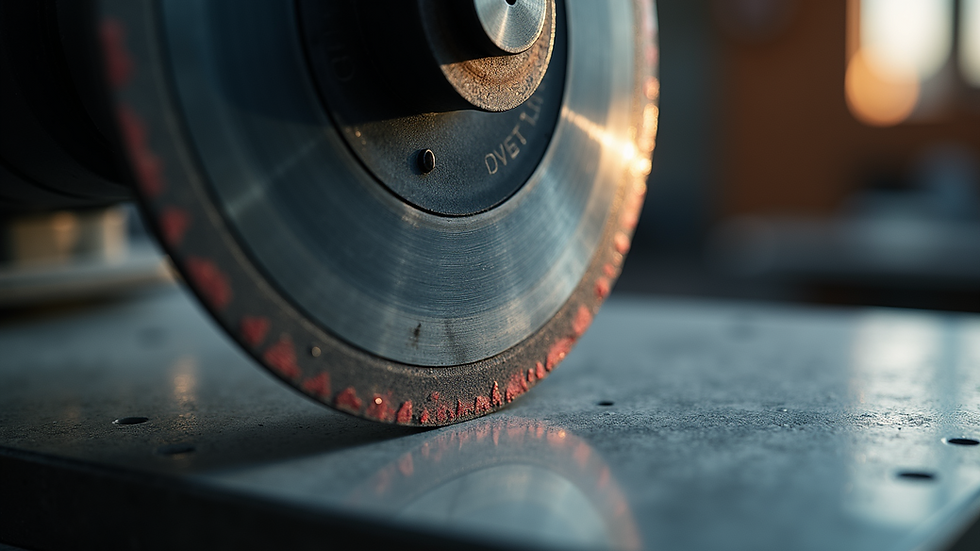

Diamond grinding methods involve using diamond-embedded tools to grind, shape, or polish hard materials like concrete, stone, ceramics, and metals. The key advantage here is the hardness of diamonds, which allows for faster material removal and longer tool life compared to conventional abrasives.

There are several diamond grinding methods, each suited for specific applications:

Surface Grinding: This method smooths flat surfaces using diamond grinding wheels or discs. It’s ideal for preparing concrete floors or finishing metal parts.

Cylindrical Grinding: Used for shaping cylindrical parts, this method employs diamond grinding wheels to achieve precise diameters and smooth finishes.

Centerless Grinding: This technique grinds the outer surface of cylindrical parts without the need for centers, using diamond tools for high precision.

Profile Grinding: Here, diamond grinding wheels are shaped to match the contour of the workpiece, perfect for complex shapes and molds.

Each method requires careful selection of the diamond grit size, bond type, and grinding speed to optimize results. For example, coarser grits remove material quickly but leave a rougher finish, while finer grits produce smoother surfaces but take longer.

Practical Tip:

Start with a coarser grit to remove bulk material, then switch to finer grits for finishing. This two-step approach balances efficiency and quality.

Choosing the Right Diamond Grinding Tools

Selecting the right tools is crucial for successful diamond grinding. The market offers a wide range of options, from grinding wheels and discs to blades and segments. Each tool varies in diamond concentration, grit size, and bonding material.

I recommend checking out diamond grinding tools from trusted suppliers who specialize in superabrasive solutions. These tools are engineered to deliver consistent performance and durability, which is essential for industrial applications.

When choosing your tools, consider:

Material Hardness: Harder materials require tools with higher diamond concentration and tougher bonds.

Tool Shape and Size: Match the tool shape to your grinding method and workpiece geometry.

Machine Compatibility: Ensure the tool fits your grinding machine’s specifications.

Cooling Requirements: Some tools perform better with water or coolant to reduce heat and extend tool life.

Friendly Reminder:

Don’t skimp on quality. Investing in premium diamond grinding tools saves you time and money in the long run by reducing downtime and improving finish quality.

Which Tool is Used to Mine Diamonds?

You might wonder how diamonds themselves are mined before they become part of grinding tools. Mining diamonds requires specialized equipment designed to extract these precious stones from deep within the earth.

The primary tools used in diamond mining include:

Heavy-Duty Excavators and Bulldozers: These machines remove overburden and expose diamond-bearing rock.

Drills and Blasting Equipment: Used to break up hard rock formations.

Kimberlite Pipe Mining Tools: Specific tools designed to extract diamonds from kimberlite pipes, the primary source of natural diamonds.

Alluvial Mining Tools: For diamonds found in riverbeds or sediment, tools like sieves and dredges are used.

Once mined, diamonds undergo sorting and processing before being embedded into grinding tools. The quality and size of the raw diamonds directly affect the performance of the final grinding product.

Quick Fact:

Industrial diamonds used in grinding tools are often synthetic, created in labs to ensure consistent quality and availability.

Advanced Techniques to Maximize Grinding Efficiency

Now that you know the basics, let’s talk about some advanced diamond grinding techniques that can boost your productivity and finish quality.

1. Multi-Pass Grinding

Instead of trying to achieve the final finish in one go, use multiple passes with progressively finer diamond grits. This reduces tool wear and heat buildup, resulting in a smoother surface.

2. Variable Speed Grinding

Adjusting the grinding speed based on the material and tool can prevent overheating and extend tool life. Slower speeds are better for delicate finishes, while higher speeds remove material faster.

3. Coolant Application

Using water or specialized coolants during grinding helps dissipate heat, reduce dust, and improve surface finish. Make sure your equipment supports coolant delivery.

4. Automated Grinding Systems

For high-volume production, automated grinding machines equipped with diamond tools can maintain consistent pressure and speed, reducing human error and increasing throughput.

5. Tool Dressing

Regularly dressing your diamond grinding wheels restores their cutting ability by exposing fresh diamonds and removing clogged debris.

Pro Tip:

Keep a log of your grinding parameters and results. Over time, this data helps you fine-tune your process for optimal performance.

Future Trends in Diamond Grinding Technology

The world of diamond grinding is evolving rapidly, driven by advances in materials science and automation. Here are some trends to watch:

Nanodiamond Coatings: These ultra-fine diamond particles improve tool sharpness and longevity.

Hybrid Bonding Systems: Combining resin and metal bonds for better flexibility and durability.

Smart Grinding Machines: Equipped with sensors and AI to monitor tool wear and adjust parameters in real-time.

Eco-Friendly Coolants: New coolant formulations reduce environmental impact without sacrificing performance.

Staying updated with these innovations can give you a competitive edge and help you meet increasingly stringent industry standards.

I hope this deep dive into advanced diamond grinding methods has sparked some ideas for your next project. Remember, the right tools and techniques make all the difference. If you want to explore high-quality diamond grinding tools, Hans is a great place to start. Their expertise in superabrasive solutions can help you tackle even the toughest grinding challenges with confidence.

Happy grinding!

Comments